Spark Your Curiosity

It is important to us that our customers have a thorough understanding of the solutions and services we provide. We write articles that educate and inspire heat-intensive manufacturers to reignite their operations.

FAQs on Black Diamond - Nitride Bonded Silicon Carbide

Onex’s Black Diamond NBSiC is US-made for consistent, superior product quality and hassle-free supply timing. Onex assists customers with design support on custom-formed shape needs with the Black Diamond application, including large and complex shapes.

Superior Performance with Black Diamond

Onex’s Black Diamond NBSiC is US-made for consistent, superior product quality and hassle-free supply timing. Onex assists customers with design support on custom-formed shape needs with the Black Diamond application, including large and complex shapes.

Know Your Precast Refractories and the Challenges They Bring

Optimal product performance in the toughest environments is the goal. Knowledge of the best available technology and innovative processes are the difference between success and failure.

Onex Awarded Two Box Forge Furnace Contract

Onex, Inc., a leading Pennsylvania manufacturer supporting the forging, heat treating, die casting, non-ferrous foundries, and graphitizing industries, was recently awarded a purchase order for the supply of mutiple box forge reheat furnaces for a major supplier of specialty metal parts located in the southeast United States.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step Five

Until you receive your shape - in perfect condition - the job isn’t done and the team at Onex knows that. Whether we are shipping to our customer or yours, Onex will provide seamless palletizing and shipping services.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step Four

Why use a furnace builder for your precast shape needs? As a furnace builder, Onex has extensive in-house furnace options for firing at different temperatures and sizes.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step Three

A lot of factors go into the mixing and pouring process including water content, material additives, mixing method, vibrating time and frequency, selecting the right mold release agent, and setting proper curing conditions. These factors all vary depending on the chemistry of the material and the size and shape of the mold.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step Two

How can experience make a difference for you? Onex’s 55 years in business gives us a depth of experience creating and building molds in shapes and sizes that other suppliers just can’t match!

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step One

What is Onex doing differently than other suppliers? We specialize in analyzing failures and problem-solving. Onex succeeds where others fail thanks to our experience, expertise, and unique perspective.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Intro

If you’re plagued by capacity issues with your precast delivery needs, there is a U.S. option with resources and space! Onex offers unique mold-making with rapid prototyping right from our Pennsylvania manufacturing facility.

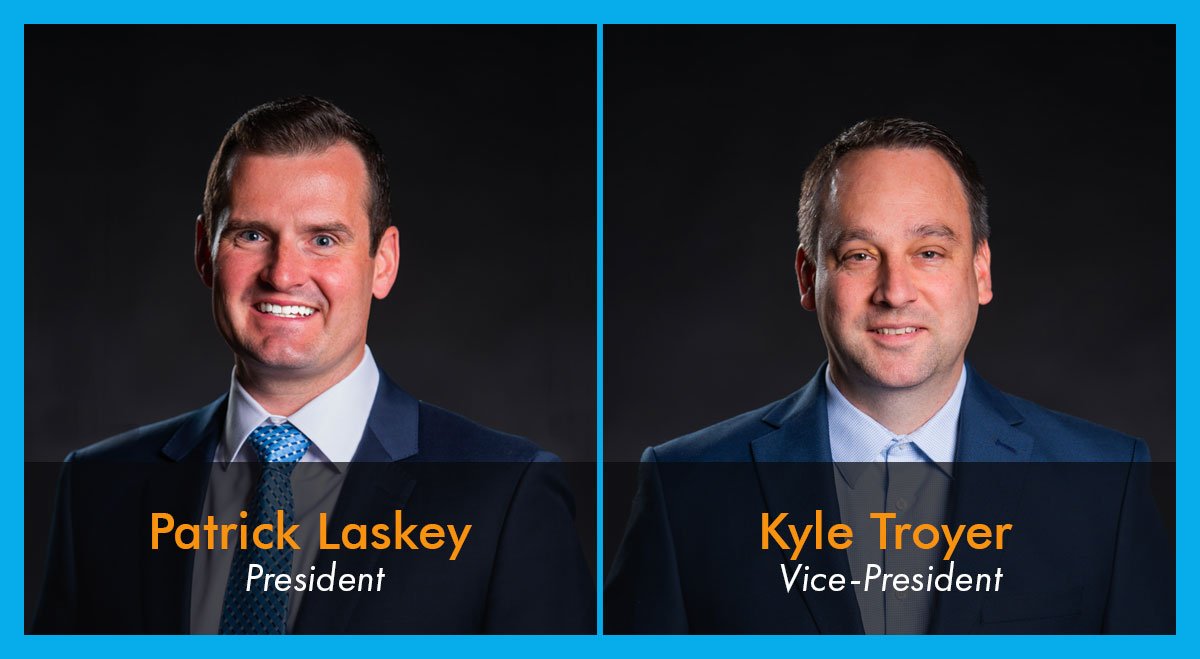

ONEX Appoints Patrick Laskey as President

Keep it Hot - Extend Refractory Life

“I’m not operating as much, so shouldn’t the refractory last as long, or longer, then when we’re running full out?” The answer is usually no because thermal cycling is refractory’s enemy.