Spark Your Curiosity

It is important to us that our customers have a thorough understanding of the solutions and services we provide. We write articles that educate and inspire heat-intensive manufacturers to reignite their operations.

ONEX, Inc. Expands into New York with Acquisition of Upstate Refractory Services

Case Study: Tip-Up Box Furnace Rebuild

At Onex Inc., every project is more than a job—it’s a test of skill, grit, and craftsmanship. This winter, we took on a full tip-up box furnace rebuild for a longtime forging partner in Western Pennsylvania. With snow on the ground and steel in the air, our team delivered a solution that was on time, on budget, and built to last.

The Employee-Owned Culture Powering Onex Inc.

At Onex, a leading American manufacturer of industrial furnaces and refractory materials headquartered in Erie, PA, the people behind our company aren’t just employees—we are owners.

Our Combustion Team Lights the Way

With the introduction of its “Combustion and Construction” division, ONEX, Inc.has created even more operational capacity and streamlined ability to serve our customers.

The Future of Construction and Refractory Services

ONEX’s new “Combustion and Construction” division, housed in our state-of-the-art 25,000-square-foot facility, positions us to take on larger, more complex projects and maintain the high standards our customers expect for refractory construction and industrial furnace systems.

Crafting Custom Shapes for Extreme Conditions

ONEX truly crafts custom-designed precast shapes, created in the same amount of time without sacrificing quality or durability.

ONEX Expands Capacity with New Facility

Onex, Inc. is excited to announce the opening of a new 25,000-square-foot facility in Erie, Pennsylvania. This new facility will house the combustion and construction business segments, allowing the Bacon Street headquarters to focus solely on precast operations.

FAQs on Black Diamond - Nitride Bonded Silicon Carbide

Onex’s Black Diamond NBSiC is US-made for consistent, superior product quality and hassle-free supply timing. Onex assists customers with design support on custom-formed shape needs with the Black Diamond application, including large and complex shapes.

Superior Performance with Black Diamond

Onex’s Black Diamond NBSiC is US-made for consistent, superior product quality and hassle-free supply timing. Onex assists customers with design support on custom-formed shape needs with the Black Diamond application, including large and complex shapes.

Know Your Precast Refractories and the Challenges They Bring

Optimal product performance in the toughest environments is the goal. Knowledge of the best available technology and innovative processes are the difference between success and failure.

Onex Awarded Two Box Forge Furnace Contract

Onex, Inc., a leading Pennsylvania manufacturer supporting the forging, heat treating, die casting, non-ferrous foundries, and graphitizing industries, was recently awarded a purchase order for the supply of mutiple box forge reheat furnaces for a major supplier of specialty metal parts located in the southeast United States.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step Five

Until you receive your shape - in perfect condition - the job isn’t done and the team at Onex knows that. Whether we are shipping to our customer or yours, Onex will provide seamless palletizing and shipping services.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step Four

Why use a furnace builder for your precast shape needs? As a furnace builder, Onex has extensive in-house furnace options for firing at different temperatures and sizes.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step Three

A lot of factors go into the mixing and pouring process including water content, material additives, mixing method, vibrating time and frequency, selecting the right mold release agent, and setting proper curing conditions. These factors all vary depending on the chemistry of the material and the size and shape of the mold.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step Two

How can experience make a difference for you? Onex’s 55 years in business gives us a depth of experience creating and building molds in shapes and sizes that other suppliers just can’t match!

Domestic Engineered Solutions for Your Toughest Precast Challenges: Step One

What is Onex doing differently than other suppliers? We specialize in analyzing failures and problem-solving. Onex succeeds where others fail thanks to our experience, expertise, and unique perspective.

Domestic Engineered Solutions for Your Toughest Precast Challenges: Intro

If you’re plagued by capacity issues with your precast delivery needs, there is a U.S. option with resources and space! Onex offers unique mold-making with rapid prototyping right from our Pennsylvania manufacturing facility.

Give Your Forge a Boost with an Elevated Combustion Design

There are hundreds of considerations to make when optimizing your combustion design. To ensure you’re investing wisely, our 3rd article of this 3-part series breaks down the important features of an optimal forge furnace combustion design. Manufacturing is coming back strong–especially in the metal processing and heat-treating industries! So, Onex is here to help you determine what you need in order to meet that growing demand. And a key part of our process is designing super-efficient combustion systems.

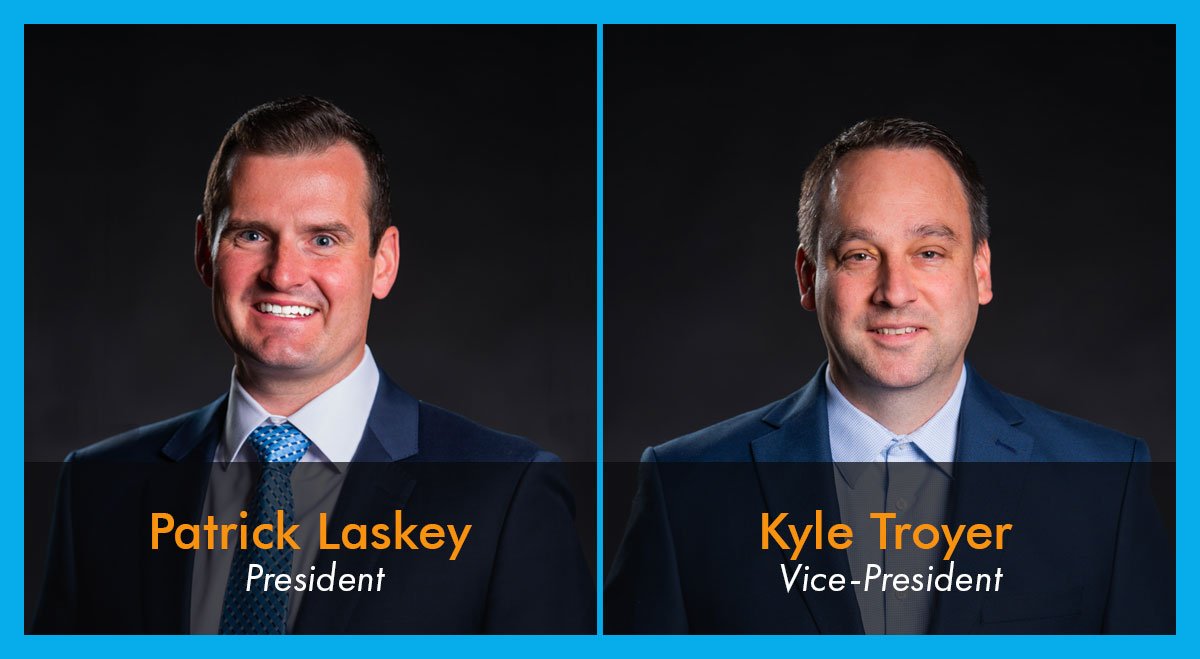

ONEX Appoints Patrick Laskey as President

Refractory Design for Optimizing Your Forge Furnace Operations

In this article, Chapter 2 of this 3-part series, we break down the elements of an efficient refractory design.